Categories

Hot Products

Custom logo printed luxury round white paper tube empty product packaging round cylinder box for perfume bottles packiging Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Elegant custom white hot stamping logo luxury rigid beauty perfume bottle packaging gift cardboard paper box with insert Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Customized luxury essential oil bottle gift cardboard cosmetic drawer paper sample box packaging black perfume boxes Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom design red rigid square solid drawer sliding perfume jewellery gift paper carton cardboard box packaging Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom design rigid square drawer sliding perfume gift paper cardboard box packaging Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom empty luxury gift cardboard drawer box packaging wholesale cosmetic perfume paper boxes Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Luxury cylinder cosmetic container empty 50ml 100ml round glass perfume atomizer bottle cardboard paper tube gift packaging box Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom Black Special Paper Double Open Door Luxury Insert Eva Cardboard Essential Oil Perfume Bottle Paper Packaging Gift Box Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom logo printed round cylinder perfume bottle cardboard paper box luxury tube perfume gift packaging box Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom Luxury Rigid Magnetic Paper Gift Packaging 30 ml 50 ml 100ml set empty glass perfume bottles with box Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

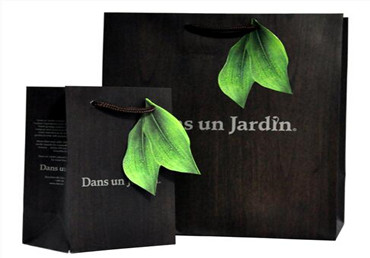

Laminated film refers to the use of transparent plastic film on the surface of the printed matter by hot pressing to protect and increase gloss. Laminating is a main process of post-press processing, which requires the surface to be clean, flat, not fuzzy, wrinkle-free, and non-foaming. After the paper bag is covered with a film, the paper bag can be protected from wear and tear, and the printed pattern can be more bright and not easily damaged, thereby extending the service life of the handbag. At the same time, plastic films can also protect against moisture, water, dirt, abrasion, folding, and chemical corrosion. The effects caused by different lamination processes are also different. If it is a sub-lamination, the color of the paper bag will be darker than the front of the lamination, which is more stable and elegant, and the bright film will look more bright and bright. The lamination process has been widely used in the printing industry. Common lamination packaging products include paper cartons, paper shoping bag, stickers, etc.

In daily life, we can often see consumers rushing to buy every make-up product launched by a brand they trust. In fact, cultivating a large number of loyal brand ambassadors is not an easy task, which requires a lot of effort, especially for a small cosmetics company. In such a lucrative industry, there are countless competitors who spend millions of dollars on marketing each year. Big company brands have long been engraved in people's minds. To succeed in this industry, cosmetics companies need to distinguish themselves from their competitors. Effective brand promotion through eye shadow packaging is a way to motivate people to buy products. 1.Simple and eye-catching packaging box design People first recall everything they see through colors, shapes, symbols, and text. Simple and eye-catching eyeshadow box design can take advantage of outstanding color combinations for good results. Although the minimalist design is simple, do not ignore the details of the packaging. 2.Use packaging technology to increase luxury effect Using the stereo UV hot stamping process can add a luxurious effect to your makeup paper packaging. Bronzing is visually appealing and can bring stunning visual effects to your products. The touch of your eyeshadow palette packaging can influence consumer decisions. Using embossing and embossing can add a new dimension to your brand logo and graphics. 3. Tell your brand story through the box Your brand story can make your brand unique. Using the box to tell your brand story will establish a good connection between the brand and the consumer.

1: letterpress box printing The printing method where the printed text is higher than the blank part, and ink is applied around the graphic, and the pressure is used to make the print imprinted on the surface of the printed matter is called letterpress printing. 2: Offset color box printing (offset printing) Now, it is customary to call offset printing as lithographic printing. The graphics and blanks of the printing plate are on the same plane. The principle of oil-water separation allows the graphics and text to be finally transferred to the surface of the printed matter. 3: Gravure box printing Gravure printing and letterpress printing are just the opposite. The graphic part is concave, while the blank part still maintains the original plane. The graphic part receives the ink layer, and the pressure of the printing cylinder is used to transfer the ink layer to the surface of the printed matter to reproduce the printed matter. 4: Filtered box printing Screen printing is typical of filter printing. The ink penetrates through the mesh (text) of the fabric, and is copied into the text on the surface of the substrate. In addition to the above four printing methods, according to the development of the times, we have developed two new printing methods: flexographic printing and special printing. 5: Flexographic box printing (letter printing) The flexographic plate was named aniline printing because of the use of volatile liquid color inks made of aniline dyes. The printing plate used a rubber plate. However, with the development of science and technology, plates and inks have changed greatly, and flexographic printing has become today's flexographic printing. 6: Special color box printing According to different printing materials and processes, special printing can be divided into: gold and silver printing; anodized aluminum stamping; embossing embossing; die-cutting indentation; metal printing; sticker printing; glazing and pasting; three-dimensional printing; hair Bubble printing; inkjet printing; holographic printing and so on.

Welcome to our booth in Paris on 29 Jan - 30 Jan 2020

Varnishing refers to coating or printing a layer of colorless and transparent ink or raw material on the surface of printed matter (commonly known as "varnish"). After drying or even calendering, the surface gloss and smoothness of printed matter are greatly increased , Highlighting the grade of printed matter. Secondly, glazing can improve the abrasion resistance of the printed surface and protect the graphics of printed products. For printed finished products that have been processed, the common practice is to use silk screen UV glazing and coating glazing, while the more advanced glazing is to be completed at the same time as on-line operation and printing. Of course, these kinds of glazing effects are also different. The most important purpose of glazing is to add value to packaging and printed matter. Because the surface adds bright gloss and three-dimensional sense, the appearance texture is more refined, and it is easier to become a visual focus in a variety of product furnishings. On the surface of paper prints, there are many types of varnishes according to the way of light coating, such as: coating varnish, UV varnish, flexo varnish, etc., then we should choose varnish How to choose? The quality of printed varnishes depends largely on the varnish used. There are three types of varnishes: oily varnish, waterborne varnish, and UV varnish. Oily varnishes contain volatile solvents, which have a negative impact on health and are not conducive to environmental protection. In contrast, water-based varnishes and UV varnishes will take more share in the market. Whether it is UV varnish, water-based varnish, ordinary varnish, or special processing, each has its advantages and disadvantages. Certain market demand, but water-based glazing is undoubtedly the most advantageous, because it is healthy and environmentally friendly, low in price, and widely used.

Because the main raw material of spot color printing gold ink is brass powder, it is a chemically active metal, which is prone to discoloration after exposure to air. Therefore, we should pay attention to the following situations when printing gold ink: 1. If gold ink comes into contact with acids, alkalis, carbon and sulfides, it will produce different degrees of chemical changes, reduce the gloss of the metal, the gold ink will look black, and the gold ink should be avoided for printing on large areas. The paper produced by the acid papermaking process is acidic. After printing, the gold ink not only changes color, but also loses gloss. 2. The use of gold ink should master the principle of printing with adjustment, that is, the amount of one preparation should be suitable for continuous printing for about 3 hours, so as not to adjust too much to make the gold powder in the oil for a long time, or contact with the air for a long time to oxidize Spoils and loses its golden luster. 3. The speed of gold ink printing should not be too fast, because the frictional heat of the ink roller will increase correspondingly due to the fast speed of the machine, which will easily make the gold ink oxidize and blacken. Therefore, the speed of printing gold should be controlled at about 3,000 sheets / hour. 4. The semi-finished products of printing gold ink should not be stacked too much, otherwise the heat released by the gold ink during the drying process on the paper surface cannot be dissipated as soon as possible, and the gold ink will be oxidized and discolored. 5. If gold ink is printed on the background color, care should be taken to properly add dry oil to the background color to avoid overprinting the gold ink when the background ink is not dry, which will affect the gloss color of the gold ink. Shenzhen Top&Top Printing Co.,ltd engaged in book printing and cosmetic paper packaging for more 10 years.We provide professional solutions.If you have any questions about the printing and packaging,please feel free to contact with us.

Established in 2005,SHENZHEN TOP&TOP PRINTING PACKING CO., LTD Located in Shenzhen city, occupied 6800 square meters, and has more than 600 workers. We are a professional enterprise that specializes in developing, designing , producing and selling of printing packing products. Our main products include double paper cosmetic box, printing servic...

© Copyright: 2026 Shenzhen Top&Top Printing Packing Co., Ltd. All Rights Reserved.

Friend link :

Glassware Supplier