Categories

Hot Products

Custom logo printed luxury round white paper tube empty product packaging round cylinder box for perfume bottles packiging Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Elegant custom white hot stamping logo luxury rigid beauty perfume bottle packaging gift cardboard paper box with insert Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Customized luxury essential oil bottle gift cardboard cosmetic drawer paper sample box packaging black perfume boxes Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom design red rigid square solid drawer sliding perfume jewellery gift paper carton cardboard box packaging Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom design rigid square drawer sliding perfume gift paper cardboard box packaging Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom empty luxury gift cardboard drawer box packaging wholesale cosmetic perfume paper boxes Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Luxury cylinder cosmetic container empty 50ml 100ml round glass perfume atomizer bottle cardboard paper tube gift packaging box Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom Black Special Paper Double Open Door Luxury Insert Eva Cardboard Essential Oil Perfume Bottle Paper Packaging Gift Box Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom logo printed round cylinder perfume bottle cardboard paper box luxury tube perfume gift packaging box Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom Luxury Rigid Magnetic Paper Gift Packaging 30 ml 50 ml 100ml set empty glass perfume bottles with box Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom perfume bottle with box This picture shows a series of high-end cosmetics and perfume products with blue and gold as the main colors. These products are placed on the display rack, providing different visual layers. In terms of color, the product packaging mostly uses a combination of dark blue and gold, which makes the whole picture have a strong artistic beauty. Blue represents nobility and elegance, while gold symbolizes luxury and quality. This color scheme highlights the brand's pursuit of high-end market positioning. From the element point of view, there are many different types of cosmetics and packaging on display here: there are lotion glass bottles, essential oil bottles, and large-capacity perfume bottles. Each single product is very unique with the packaging. The most noteworthy thing is that the "TOP&TOP" brand logo runs through the whole process, whether it is the product itself or the packaging box. It can be seen. This not only shows that all the exhibits belong to the same brand series, but also emphasizes the company's emphasis on brand unity and the consistency of brand image.

One-Stop Custom Gift Box Solutions In today’s fast-paced world, standing out is essential. Custom gift boxes are the perfect way to make your presents memorable. A one-stop solution for custom gift boxes simplifies the process and elevates your gifting experience. Why Choose Custom Gift Boxes? 1. **Personalization**: Tailor each box to reflect the recipient's personality or occasion. From colors to designs, every detail can be customized. 2. **Branding**: For businesses, custom gift boxes enhance brand visibility. Include your logo and colors to create a lasting impression. 3. **Versatility**: Whether it’s for birthdays, weddings, or corporate events, these boxes cater to all occasions. They can hold anything from gourmet treats to luxury items. 4. **Quality Materials**: High-quality materials ensure that your gifts are not only beautiful but also durable. Choose from eco-friendly options for a sustainable touch. #### The Process Made Easy 1. **Design Consultation**: Start with a design consultation to discuss your vision and preferences. 2. **Sample Creation**: Receive samples before finalizing the design, ensuring everything meets your expectations. 3. **Production**: Once approved, production begins swiftly without compromising quality. 4. **Delivery Options**: Enjoy flexible delivery options tailored to your timeline and needs. #### Benefits of One-Stop Solutions - **Time-Saving**: No need to juggle multiple vendors; everything you need is in one place. - **Cost-Effective**: Bulk orders often come with discounts, making it budget-friendly for businesses and individuals alike. - **Expert Guidance**: Access professional advice on design trends and packaging solutions that best suit your gifts. #### Conclusion Custom gift boxes are more than just packaging; they’re an extension of thoughtfulness and creativity. With a one-stop solution, you can effortlessly create stunning presentations that leave a lasting impression on recipients. Elevate your gifting game today!

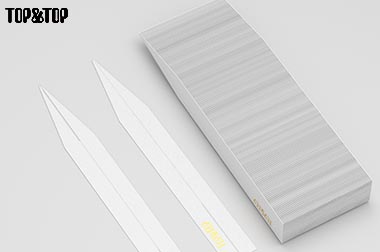

The Ultimate Guide to Using Perfume Test Papers Perfume test papers are a great tool for trying out different scents before committing to a full-size bottle. These small strips of paper allow you to sample a fragrance without having to apply it directly to your skin. Here's everything you need to know about using perfume test papers effectively. 1. How to Use Perfume Test Papers: - Simply spray the desired perfume onto the test paper from a distance of about 6 inches. - Wait for a few seconds for the alcohol in the perfume to evaporate, allowing the true scent of the fragrance to come through. - Hold the test paper up to your nose and take a deep breath to fully experience the scent. 2. Benefits of Using Perfume Test Papers: - Test papers allow you to sample multiple fragrances at once without them mixing on your skin. - They are convenient and easy to carry with you while shopping for perfumes. - You can compare different scents side by side on test papers before making a decision. 3. Tips for Using Perfume Test Papers: - Use separate test papers for each fragrance to avoid mixing scents. - Write down the name of each perfume on the test paper so you can remember which one is which. - Allow the scent of the perfume to develop fully on the test paper before making a judgment. In conclusion, perfume test papers are a handy tool for exploring new fragrances and finding your perfect scent. By following these tips and techniques, you can make the most out of your perfume testing experience. Happy sniffing!

Are you looking for the perfect packaging solution for your perfume samples? Look no further than custom carton boxes designed specifically for 1ml, 2ml, 3ml, 5ml, and 10ml vial spray bottles. These boxes are ideal for showcasing your perfume samples in a professional and attractive way. The custom carton boxes are perfect for displaying your perfume samples at trade shows, events, or even as gifts to customers. The sturdy construction of the boxes ensures that your samples are protected during transportation and storage. With the option to customize the design of the box with your brand logo or artwork, you can create a unique and eye-catching packaging solution that will help your perfume samples stand out from the competition. Whether you prefer a sleek and modern design or a more traditional look, these custom carton boxes can be tailored to suit your brand's aesthetic. Say goodbye to boring packaging solutions and elevate the presentation of your perfume samples with custom carton boxes designed specifically for 1ml, 2ml, 3ml, 5ml, and 10ml vial spray bottles. Your customers will be impressed by the attention to detail and professionalism displayed in every aspect of your product presentation.

When it comes to gift packaging for candles, custom candle paper boxes are a great choice. These boxes are not only stylish and eye-catching but also provide a practical way to store and display candles. Custom candle paper boxes come in a variety of shapes, sizes, and designs to suit any occasion or theme. Whether you're looking for a sleek and modern box for a contemporary candle design or a more traditional box for a classic candle scent, there is an option to fit your needs. In addition to their aesthetic appeal, custom candle paper boxes also offer practical benefits. They provide protection for the candles during shipping and storage, ensuring that they arrive in perfect condition. The sturdy construction of these boxes also helps prevent damage from occurring during handling. Furthermore, custom personalized candle paper boxes can be personalized with your brand logo or message, making them ideal for promotional purposes. By adding your own unique touch to the packaging, you can create a memorable unboxing experience for your customers. Overall, custom candle paper boxes are a versatile and practical choice for gift packaging. Whether you're looking to enhance the presentation of your candles or promote your brand, these boxes are sure to make a lasting impression on recipients.

The Significance of the Dragon Boat Festival The Dragon Boat Festival, also known as Duanwu Festival, is a traditional Chinese holiday that is celebrated on the fifth day of the fifth month of the lunar calendar. This festival has a rich history and cultural significance in Chinese society. One of the main reasons for celebrating the Dragon Boat Festival is to commemorate the death of Qu Yuan, a famous poet and minister from ancient China. Qu Yuan was known for his loyalty to his country and his people, but he was exiled by corrupt officials. In despair, he drowned himself in the Miluo River. To prevent fish from eating his body, people threw rice dumplings into the river and raced dragon boats to scare away evil spirits. Today, people celebrate the Dragon Boat Festival by eating zongzi (rice dumplings), racing dragon boats, and hanging up icons of Zhong Kui (a mythological figure who protects against evil spirits). The festival is a time for families to come together, honor their ancestors, and pray for good health and fortune. In addition to its historical roots, the Dragon Boat Festival also symbolizes unity and strength. The act of racing dragon boats requires teamwork and coordination among team members. It promotes camaraderie and cooperation among participants. Overall, the Dragon Boat Festival holds great significance in Chinese culture as it pays tribute to a revered historical figure, promotes unity among communities through dragon boat races, and brings families together to celebrate tradition and heritage.

Established in 2005,SHENZHEN TOP&TOP PRINTING PACKING CO., LTD Located in Shenzhen city, occupied 6800 square meters, and has more than 600 workers. We are a professional enterprise that specializes in developing, designing , producing and selling of printing packing products. Our main products include double paper cosmetic box, printing servic...

© Copyright: 2026 Shenzhen Top&Top Printing Packing Co., Ltd. All Rights Reserved.

Friend link :

Glassware Supplier