Categories

Hot Products

Custom logo printed luxury round white paper tube empty product packaging round cylinder box for perfume bottles packiging Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Elegant custom white hot stamping logo luxury rigid beauty perfume bottle packaging gift cardboard paper box with insert Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Customized luxury essential oil bottle gift cardboard cosmetic drawer paper sample box packaging black perfume boxes Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom design red rigid square solid drawer sliding perfume jewellery gift paper carton cardboard box packaging Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

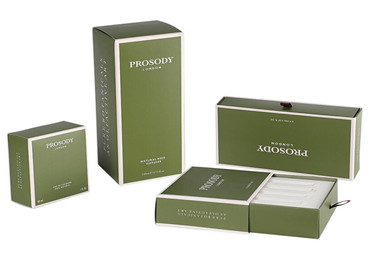

Custom design rigid square drawer sliding perfume gift paper cardboard box packaging Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom empty luxury gift cardboard drawer box packaging wholesale cosmetic perfume paper boxes Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Luxury cylinder cosmetic container empty 50ml 100ml round glass perfume atomizer bottle cardboard paper tube gift packaging box Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom Black Special Paper Double Open Door Luxury Insert Eva Cardboard Essential Oil Perfume Bottle Paper Packaging Gift Box Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom logo printed round cylinder perfume bottle cardboard paper box luxury tube perfume gift packaging box Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

Custom Luxury Rigid Magnetic Paper Gift Packaging 30 ml 50 ml 100ml set empty glass perfume bottles with box Details about Custom Gift Boxes Packaging Wholesale: One of the major benefits of custom perfume boxes is they add branding value to your products. Branding can be expressed in a variety of ways, including the use of labels, laser etching and even environmentally friendly materials. Your fragrances are left with an attractive and professional feel. It can help you stand out in the competitive market. more

For paper gift boxes, many people have questions, why is the color of the gift box changed over time? In fact, there are two reasons for the color change on the surface of the gift box: oxidation reaction and air temperature. Oxidation reaction: The composition of printing ink, there are many drying agents, antioxidants and other additives in the ink, which will not be oxidized after drying. Ink is a homogeneous mixture consisting of colored bodies (such as pigments, dyes, etc.), binders, fillers (fillers), additional materials, etc.; can be printed and dried on the body to be printed; it is colored and has a certain flow Degree of paste adhesive. Therefore, color (hue), body bone (thickness, fluidity and other rheological properties) and drying performance are the three most important properties of ink. There are many types and different physical properties, some are thick and sticky; some are quite rare. Some use vegetable oil as the linking material; some use resin and solvent or water as the linking material. These are determined according to the object to be printed, namely the substrate, printing method, type of printing plate material and drying method. Therefore, the printed part of the surface of the gift box will change color after a long time, one of the reasons is that the printing ink has not reached the standard. So if you want to get the perfect paper packaging for your products,Please feel free to contact with us,we design the paper packaging and offer a good solution for you

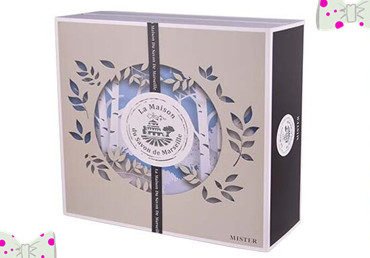

According to the design requirements, the specific paper and materials are processed on a machine equipped with a steel knife template, and the paper or material is punched into the required shape and exhibits special effects in form. This process technology is called die cutting. The specific paper and materials are processed on a machine equipped with a steel wire template according to the design requirements. The surface of the paper or material is printed with deep or light steel wire marks under the pressure, and then folded by hand or machine. And the material is very easy to bend and form a certain form of structure or shape, this process technology is called indentation. Generally, the die-cutting and creasing process is a process of combining die-cutting knives and crimping knives in the same stencil, and performing die-cutting and creasing on the die-cutting machine at the same time. In daily production, it is usually referred to as die cutting or stamping. It can be operated as a separate process or two processes can be combined into one process on the same machine. The die-cutting plate is equipped with both steel knives and steel wires without conflict. The die-cutting and creasing process has changed the single linear or flat form of the printed matter, and let all kinds of printing and packaging be presented in three-dimensional and curved lines. The various shapes and shapes created are more beautiful and refined, and are full of creative wisdom. product. In the field of paper printed products, die-cutting and creasing processes are widely used, such as common packaging cartons, special-shaped tags, hollow labels, folding DM advertising sheets, sticker printing, leather products, etc., all need to use molds in post-press processing Cutting process. Common three-dimensional packaging boxes such as rectangular parallelepiped, cube, cone, polygon structure. Flat works of different shapes such as circles, ellipses, plum blossoms, polygons, etc., and other special creative graphics that appear in book catalogs combined with a page design.

For the cosmetics industry, it is necessary to design packaging boxes that visually appeal to consumers. The fashion trends of cosmetics change with the seasons, as do gift boxes in the cosmetics industry. The most effective cosmetic packaging trends rarely stay the same for a long time. Cosmetic packaging boxes give brands an opportunity to innovate, because cosmetics provide a way for people to express themselves. There may be a variety of cosmetic packaging boxes, but it is important not to keep your brand following the trend. It needs to constantly develop and push the limits. Consider these points before customizing cosmetics to make your products more popular with consumers: 1. Printing Bold prints will be very popular this year, especially with a special texture. This makes the makeup packaging itself more attractive. Visual design can be used to convey a certain feeling. For example, French-inspired brands can add French-specific international elements. For products with a variety of shades, full-page printed cosmetic packaging can enable customers to better understand the products they purchase. 2. Craft Adding some additional packaging technology to the cosmetic packaging box can make consumers have a powerful shock whether visually or tactilely. Laminating, embossing, embossing, and bronzing can make the cosmetic packaging displayed on the shelves more attractive. With so many brands and products in the cosmetics field, it is vital to differentiate products. 3. Interior space design Many makeup lovers like to try new things, which is why some brands distribute samples every time they order, especially when customers buy online. In many cases, these samples are only provided with the product, but a more creative way of handling the samples is to include them directly in cosmetic packaging. Embedding samples can not only increase the creativity of cosmetic packaging, but also make customers feel very happy, and will continue to repurchase more products. Cosmetic packaging needn't have a standard rectangular shape. Many top beauty brands have unique packaging designs because it sticks out from other products on the shelves, so it is more attractive to the audience. Whether cosmetics are popular with consumers often depends on their first impressions of brands, products, and packaging, especially when building brand awareness with consumers, customers, and customers. When customizing cosmetics packaging boxes, we need to consider the customer's vision, touch, and the sense of pleasure generated by the product, so as to customize the more popular packaging boxes for consumers.

Clear brand identity Any new product on the cosmetics production line must have a clear brand identity, so that loyal customers can easily find the new product, and new customers who are interested in a particular cosmetics production line will also recognize the product as the brand product series a part of. Designers of many very successful cosmetic brands know that simplicity creates a high-quality image, and colorful design is a trend. It is in high-speed fashion, but it must be properly designed to maintain a high-quality image. Make sure that any new products in your product line can clearly identify your brand and add additional design elements to each unique product. Outstanding design The shelves are full of products, and the packaging design of cosmetics must stand out from many products. The factors that make cosmetic packaging more attractive are the surface treatment, color or style of the packaging carton. In a highly saturated field, excellent design is a key factor. Those cosmetics that display a high-quality image on the packaging are more attractive to consumers who browse the shelves. The science behind effective design involves design elements among consumers that create instinctive responses. These factors relate to all aspects of packaging, including color, style, craftsmanship, logo and graphics. The any cosmetics packaging is a key factor to attract consumers, especially because consumers only have two to three seconds to pay attention to, select and further investigate cosmetics. At TOP&TOP Packaging, our team of professional designers brings a wealth of knowledge and experience to cosmetic packaging design. Our creative, high-impact packaging design is ultimately customizable, we have the ability to produce a full range of product packaging services on our most advanced printing equipment, which can help your cosmetic brand have the greatest impact on consumers

The color matching of the makeup packaging design plays a crucial role in determining the customer's first impression of a brand or product. Color plays an important role in make-up packaging. It can determine consumer sentiment and affect its behavior. The Pantone Color Institute chooses an annual color every year, and it has been doing this for the past 20 years. After well-thought-out applications, popular colors can help brands keep up with trends and meet consumer expectations for new things. For example, in 2016, crystal powder was the popular color of the year and was also commonly known as "millennial powder". It has penetrated into many industries. In addition to being used in cosmetic packaging boxes, even from fashion to interior decoration, and even electronic products, rose elements are everywhere. According to Pan Tong, live coral was the last year's popular color because it is a vivid color that reflects life, although its edges are relatively soft. With the recent vigorous promotion of environmental protection packaging, many companies will reflect this through the color matching of color cosmetic packaging boxes, not only to remind everyone to pay attention to environmental protection through color, but also reflect this on product packaging boxes. For example, use recyclable packaging materials. Color can make product packaging famous in many packaging designs, so it is very important for brands to understand how color and consumer psychology are intertwined. Packaging colors and consumer expectations With the rapid development of technology and artificial intelligence, many people are eager for warmth and humanity, and the warm color makeup box can make consumers feel warm and happy. Most consumers spend a lot of time online, especially on social media. Brands can take advantage of this. The warm and humanistic tones are likely to attract shoppers ’attention. All of these are important to influence consumer psychology, which will make shoppers feel warm and popular. Gradient Over the past few years, another trend in packaging design has been gradual change. The main color is matched with similar colors to form a soft gradient. Such as red, orange and yellow, they can blend well with pink. Combined, these colors can form a gradient that will effectively grab shoppers ’attention. Popular colors It is easy to keep the popular trends and easily interweave the famous brand logos. Adding a popular color in "Best Color of the Year" or setting it as a background color makes it easy to upgrade any make-up packaging to make it a trend immediately. The simple color matching also adds warmth and fun, making the packaging design more attractive. Elements of color Another complicated method to make the packaging have the latest popular color is to simply apply the color element to its design. Adding color to the element itself can enhance the design. Simple graphics, even structure and shape can be consistent with the annual color. Color tre...

Nail polish is one of the most attactive products for many girls. So packaging paper boxes can help the manufacturers to protect the products,what is more,custom printed nail polish packaging boxes can also make more sales.and get more market. There are too many nail polish boxes that are placed on the shelve.but do you know the reason if a customer chooses your products? The most important reson is your packaging that is unique and outstanding.another feature is that the packaging should be sturdy so that it can protect the bottle inside. Printing can make your paper cosmetic box more beautiful.you can choose different printing,like CMYK,PMS or textured techniques to create more effects. And you can use different finishing potions in cluding,lamination,matte lamination,gloss lamination,gloss UV,mattte UV,Embossing or foiling. Good finishing and printing will give your customers an idea that you can produce a quality products. If you are new in packaging.Please contact with us,we will provide you with stlish custom printed cosmetic boxes based on your demands.

Established in 2005,SHENZHEN TOP&TOP PRINTING PACKING CO., LTD Located in Shenzhen city, occupied 6800 square meters, and has more than 600 workers. We are a professional enterprise that specializes in developing, designing , producing and selling of printing packing products. Our main products include double paper cosmetic box, printing servic...

© Copyright: 2026 Shenzhen Top&Top Printing Packing Co., Ltd. All Rights Reserved.

Friend link :

Glassware Supplier